Small business managing inventory is a critical aspect of running a successful operation. Effective inventory management can help businesses reduce costs, increase efficiency, and improve customer satisfaction. This comprehensive guide will delve into the key principles, methods, and strategies for managing inventory in a small business setting, empowering entrepreneurs with the knowledge and tools they need to optimize their operations and drive growth.

Understanding the importance of inventory management, the challenges small businesses face, and the benefits of implementing effective strategies will set the stage for the discussion.

Understanding Small Business Inventory Management

Inventory management is crucial for small businesses as it ensures they have the right products in stock to meet customer demand, while avoiding overstocking and wastage. Poor inventory management can lead to lost sales, higher storage costs, and reduced profit margins.

Getting Started with Inventory Management

Small businesses can implement inventory management practices by:

- Conducting regular inventory audits to track stock levels.

- Using inventory management software to automate processes and improve accuracy.

- Establishing minimum and maximum stock levels to avoid overstocking or shortages.

- Implementing inventory forecasting techniques to predict future demand.

- Outsourcing inventory management to third-party providers for specialized expertise and cost-saving.

Methods for Managing Inventory

Effective inventory management is crucial for small businesses to optimize stock levels, minimize waste, and ensure customer satisfaction. Several inventory management methods are available, each with its advantages and disadvantages. Understanding the different methods and choosing the right one can help small businesses streamline their inventory operations.

FIFO (First-In, First-Out)

FIFO assumes that the oldest inventory items are sold first. This method is commonly used in industries where products have a limited shelf life, such as food and beverages. By selling older items first, businesses can reduce the risk of spoilage and ensure that customers receive fresh products.

LIFO (Last-In, First-Out)

LIFO assumes that the most recently acquired inventory items are sold first. This method can be advantageous in periods of inflation, as it allows businesses to report lower cost of goods sold (COGS) and higher profits. However, LIFO can also lead to higher inventory carrying costs during periods of deflation.

ABC Analysis

ABC analysis is a technique used to classify inventory items based on their value and importance. Items are typically categorized into three groups: A (high-value, low-volume), B (medium-value, medium-volume), and C (low-value, high-volume). This analysis helps businesses prioritize inventory management efforts and focus on items that have the greatest impact on profitability.

| Method | Advantages | Disadvantages |

|---|---|---|

| FIFO |

|

|

| LIFO |

|

|

| ABC Analysis |

|

|

Choosing the Right Inventory Management Method

The best inventory management method for a small business depends on several factors, including the type of industry, the nature of the products, and the business’s financial situation. Businesses should consider the following when choosing a method:

- Product shelf life

- Inventory turnover rate

- Inflationary or deflationary economic conditions

- Business’s financial goals

By carefully evaluating these factors and understanding the different inventory management methods, small businesses can choose the approach that best meets their specific needs and helps them optimize their inventory operations.

Inventory Control Techniques

Inventory control techniques are essential for small businesses to effectively manage their inventory levels and minimize losses. By implementing effective inventory control techniques, businesses can improve their profitability, reduce waste, and enhance customer satisfaction.

Some of the most common inventory control techniques used by small businesses include:

- Cycle counting:Regularly counting a portion of inventory to identify discrepancies between physical inventory and inventory records.

- Safety stock levels:Maintaining a buffer of inventory to protect against unexpected fluctuations in demand or supply.

- First-in, first-out (FIFO):Issuing inventory in the order it was received, ensuring that older inventory is used first.

- Last-in, first-out (LIFO):Issuing inventory in the reverse order it was received, resulting in the most recently purchased inventory being used first.

Technology in Inventory Control

Technology can play a vital role in inventory control by automating processes, improving accuracy, and providing real-time data. Inventory management software can help businesses track inventory levels, manage purchase orders, and generate reports to support decision-making.

By leveraging technology, small businesses can streamline their inventory control processes, reduce errors, and gain valuable insights into their inventory performance.

Inventory Optimization Strategies

Inventory optimization is a critical aspect of inventory management that aims to strike a balance between holding sufficient stock to meet customer demand and minimizing the associated costs. It involves determining the optimal inventory levels to maximize profitability and efficiency.

By optimizing inventory levels, small businesses can reduce carrying costs, prevent stockouts, improve cash flow, and enhance customer satisfaction. To achieve inventory optimization, businesses can follow a step-by-step guide:

Step 1: Establish Realistic Demand Forecasts

Accurate demand forecasting is crucial for determining appropriate inventory levels. Businesses should analyze historical sales data, consider seasonality, market trends, and customer behavior to develop reliable forecasts.

Step 2: Set Safety Stock Levels

Safety stock serves as a buffer against unexpected fluctuations in demand or supply chain disruptions. The optimal safety stock level depends on the product’s lead time, demand variability, and the desired service level.

Step 3: Implement Inventory Control Techniques

Effective inventory control techniques, such as ABC analysis, periodic or perpetual inventory systems, and reorder point calculations, help businesses monitor and manage inventory levels efficiently.

Step 4: Leverage Technology

Inventory management software and analytics tools can automate tasks, provide real-time data, and generate insights to optimize inventory levels. These tools can streamline processes, improve accuracy, and reduce manual errors.

Step 5: Monitor and Adjust

Inventory optimization is an ongoing process that requires regular monitoring and adjustment. Businesses should track key performance indicators, such as inventory turnover, stockout rates, and carrying costs, to identify areas for improvement and make necessary adjustments.

Examples of Successful Inventory Optimization Strategies

Many small businesses have successfully implemented inventory optimization strategies to improve their operations and profitability. Here are a few examples:

- A small retail store used ABC analysis to identify high-value items and implemented a just-in-time inventory system to reduce carrying costs.

- A manufacturing company implemented a perpetual inventory system and automated reorder point calculations to prevent stockouts and ensure timely production.

- An online retailer leveraged inventory management software to analyze sales patterns and optimize safety stock levels, reducing overstocking and improving customer satisfaction.

Inventory Forecasting and Planning

Inventory forecasting is crucial for small businesses to optimize stock levels, minimize waste, and meet customer demand effectively. By accurately predicting future inventory needs, businesses can make informed decisions regarding purchasing, production, and storage.

Forecasting Methods

Various forecasting methods exist, each with its advantages and limitations. Common methods include:

- Historical Data Analysis:Uses past sales data to identify trends and patterns.

- Moving Average:Calculates the average of sales over a specific period, smoothing out fluctuations.

- Exponential Smoothing:Assigns greater weight to recent data, responding more quickly to changes in demand.

The choice of forecasting method depends on factors such as the availability of historical data, the nature of the business, and the desired level of accuracy.

Creating an Inventory Plan

Based on inventory forecasts, businesses can create an inventory plan that Artikels the target inventory levels, safety stock, and replenishment schedules. The plan should consider:

- Lead Time:The time it takes to receive inventory from suppliers.

- Safety Stock:Additional inventory held to buffer against unexpected fluctuations in demand or supply.

- Reorder Point:The inventory level at which a new order should be placed.

- Order Quantity:The amount of inventory to order at each replenishment.

Effective inventory planning helps businesses maintain optimal inventory levels, reduce costs, and improve customer satisfaction by ensuring product availability.

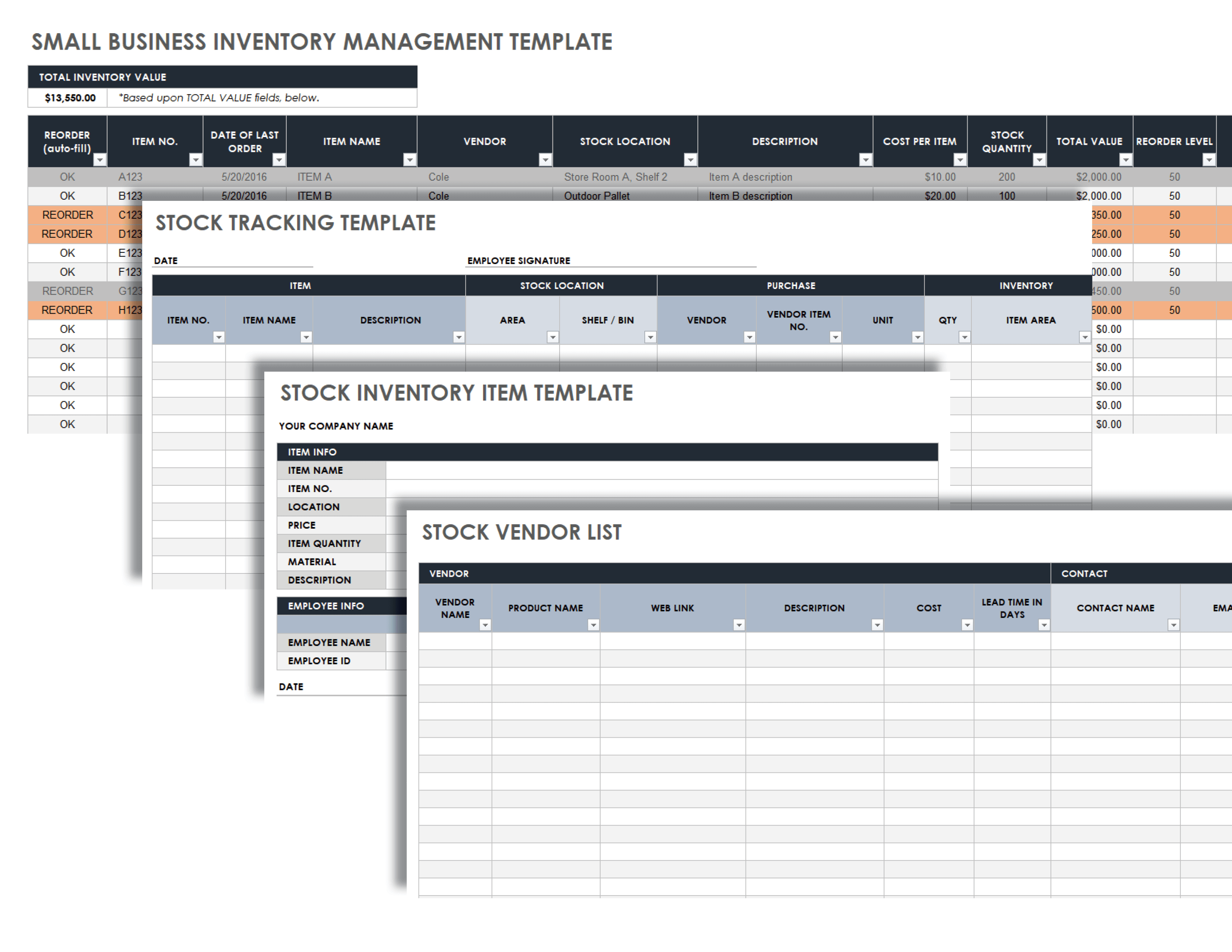

Inventory Management Tools and Resources: Small Business Managing Inventory

Inventory management is a crucial aspect of small business operations. Small businesses can leverage various tools and resources to streamline inventory management, improve accuracy, and enhance efficiency.

Inventory Management Software

Inventory management software is a powerful tool that automates many aspects of inventory management. These software solutions provide features such as:

- Real-time inventory tracking

- Order processing and fulfillment

- Purchase order management

- Reporting and analytics

Inventory management software can significantly improve inventory accuracy, reduce manual errors, and save time and resources.

Comparison of Inventory Management Software, Small business managing inventory

| Software | Features | Pricing ||—|—|—|| QuickBooks | Basic inventory management, invoicing, and reporting | Starts at $15/month || Zoho Inventory | Advanced inventory management, multi-channel selling, and analytics | Starts at $49/month || NetSuite | Comprehensive inventory management, CRM, and e-commerce capabilities | Starts at $999/month |

Inventory Management Apps

Inventory management apps offer a convenient and mobile-friendly way to manage inventory on the go. These apps typically provide features such as:

- Barcode scanning for easy inventory updates

- Stock level alerts

- Order management

- Inventory reports

Inventory management apps can be particularly useful for small businesses with a physical store or warehouse.

Online Resources

Numerous online resources are available to help small businesses manage inventory effectively. These resources include:

- Inventory management blogs and articles

- Inventory management webinars and training programs

- Online inventory management communities and forums

These resources can provide valuable insights, best practices, and support for small business owners.

Case Studies and Examples

Small businesses that have implemented successful inventory management strategies provide valuable insights into the effectiveness of various approaches. By examining real-world case studies and examples, we can identify best practices, challenges, and solutions for improving inventory management in small businesses.

One notable example is the case of a small manufacturing company that faced challenges with excessive inventory levels and high storage costs. Through the implementation of a just-in-time (JIT) inventory management system, the company reduced its inventory by 40%, leading to significant cost savings and improved cash flow.

Inventory Management Challenges and Solutions

Small businesses often encounter unique challenges in inventory management. These challenges may include:

- Limited resources and budget constraints

- Lack of specialized inventory management expertise

- Difficulty in forecasting demand accurately

- Inefficient inventory tracking systems

To overcome these challenges, small businesses can adopt various solutions, such as:

- Investing in affordable inventory management software

- Outsourcing inventory management tasks to third-party providers

- Implementing inventory control techniques like ABC analysis and cycle counting

- Collaborating with suppliers to improve forecasting and reduce lead times

Wrap-Up

In conclusion, managing inventory effectively is crucial for the success of any small business. By implementing the strategies Artikeld in this guide, entrepreneurs can gain control over their inventory, reduce costs, increase efficiency, and enhance customer satisfaction. Remember, inventory management is an ongoing process that requires regular monitoring, adjustment, and optimization to meet the ever-changing demands of the market.

Embrace the principles and best practices discussed here, and your small business will be well-positioned to thrive in today’s competitive landscape.

FAQ Corner

What are the common challenges small businesses face in managing inventory?

Small businesses often struggle with limited storage space, fluctuating demand, and managing cash flow while maintaining optimal inventory levels.

How can small businesses get started with inventory management?

Start by understanding your inventory needs, setting clear inventory goals, and choosing an inventory management method that aligns with your business model.

What are the key inventory control techniques for small businesses?

Cycle counting, safety stock levels, and regular inventory audits are essential inventory control techniques for small businesses.