Business inventory accounting tool is a vital aspect of inventory management, providing businesses with the ability to track, value, and optimize their inventory. Understanding the principles and best practices of inventory accounting is crucial for businesses to maintain accurate financial records, optimize inventory levels, and make informed decisions.

This comprehensive guide delves into the intricacies of inventory management techniques, inventory costing methods, inventory valuation, inventory control systems, and inventory optimization. We will also explore the benefits and key features of inventory management software and discuss best practices for effective inventory management.

Inventory Valuation

Inventory valuation is the process of determining the value of a company’s inventory for financial reporting purposes. It is important because it affects the company’s financial statements, such as the balance sheet and income statement.There are several different methods that can be used to value inventory, each with its own advantages and disadvantages.

Some of the most common methods include:

Lower of Cost or Market

The lower of cost or market (LCM) method values inventory at the lower of its cost or its current market value. This method is often used because it is conservative and provides a more accurate representation of the inventory’s value.

Net Realizable Value

The net realizable value (NRV) method values inventory at the estimated selling price minus any costs that would be incurred to sell the inventory. This method is often used when the inventory is not expected to be sold at its full cost.Inventory valuation is an important part of financial reporting.

It affects the company’s financial statements and can have a significant impact on the company’s financial performance.

Inventory Control Systems

Inventory control systems are crucial for businesses to effectively manage their inventory levels, minimize losses, and optimize profitability. There are two primary types of inventory control systems: periodic and perpetual.

Periodic Inventory Systems

Periodic inventory systems involve physically counting inventory at specific intervals, typically at the end of an accounting period. This system is less labor-intensive and requires fewer resources to maintain.

Advantages of Periodic Inventory Systems

- Lower operating costs compared to perpetual systems

- Less time and effort required for daily inventory tracking

Disadvantages of Periodic Inventory Systems, Business inventory accounting tool

- Limited real-time visibility of inventory levels

- Inaccurate inventory records due to potential errors during physical counts

- Difficulty in tracking inventory movement and identifying shrinkage

Perpetual Inventory Systems

Perpetual inventory systems continuously track inventory levels as transactions occur. This system provides real-time visibility of inventory on hand and allows for more accurate inventory management.

Advantages of Perpetual Inventory Systems

- Accurate and up-to-date inventory records

- Improved inventory control and reduced shrinkage

- Enhanced decision-making based on real-time inventory data

Disadvantages of Perpetual Inventory Systems

- Higher operating costs due to additional labor and technology requirements

- Requires more time and effort to maintain accurate records

Key Features of an Effective Inventory Control System

An effective inventory control system should possess the following key features:

Accuracy

The system should provide accurate and reliable inventory records.

Timeliness

The system should provide real-time or near real-time visibility of inventory levels.

Flexibility

The system should be adaptable to changing business needs and inventory management practices.

Integration

The system should integrate with other business systems, such as accounting and purchasing.

Security

The system should protect inventory data from unauthorized access and manipulation.

Inventory Optimization

Inventory optimization is crucial for businesses to streamline their inventory management processes, reduce costs, and enhance operational efficiency. It involves determining the optimal levels of inventory to hold, minimizing waste and maximizing profitability.Different inventory optimization techniques exist, each with its unique purpose:

Safety Stock

Maintaining safety stock provides a buffer against unexpected fluctuations in demand or supply chain disruptions. It ensures that businesses can meet customer demand even during peak periods or unexpected events.

Reorder Point

The reorder point is the inventory level at which a new order should be placed. Setting an appropriate reorder point helps businesses avoid stockouts while minimizing the carrying costs associated with excess inventory.

Economic Order Quantity

Economic order quantity (EOQ) is the optimal quantity of inventory to order at a time. It considers factors such as demand, ordering costs, and carrying costs to determine the most cost-effective order size.

Benefits of Inventory Optimization

By implementing effective inventory optimization techniques, businesses can:

- Reduce inventory holding costs

- Improve customer service by minimizing stockouts

- Optimize cash flow by reducing the need for excess inventory

- Enhance operational efficiency by streamlining inventory management processes

Inventory Management Software

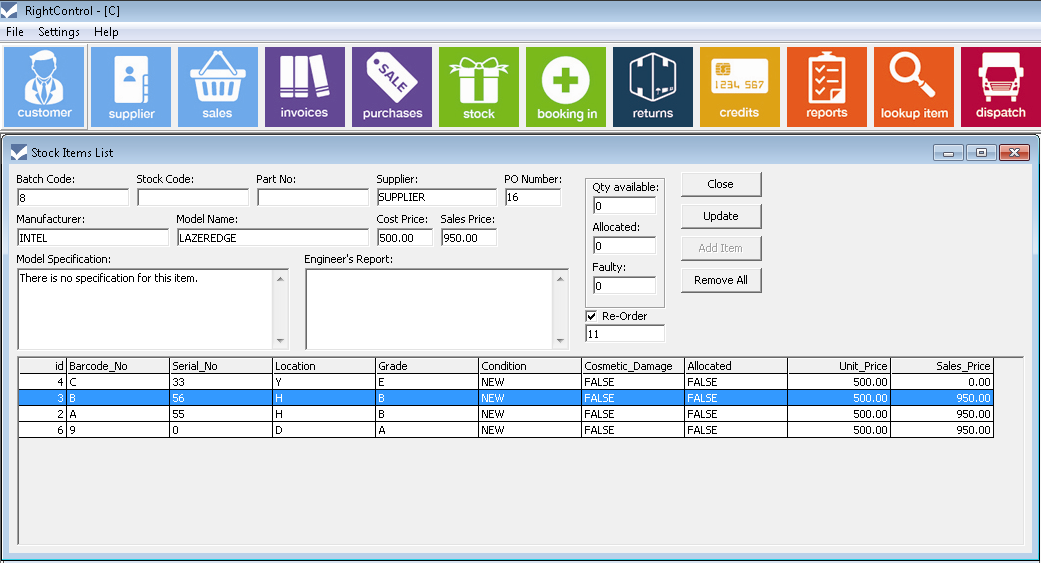

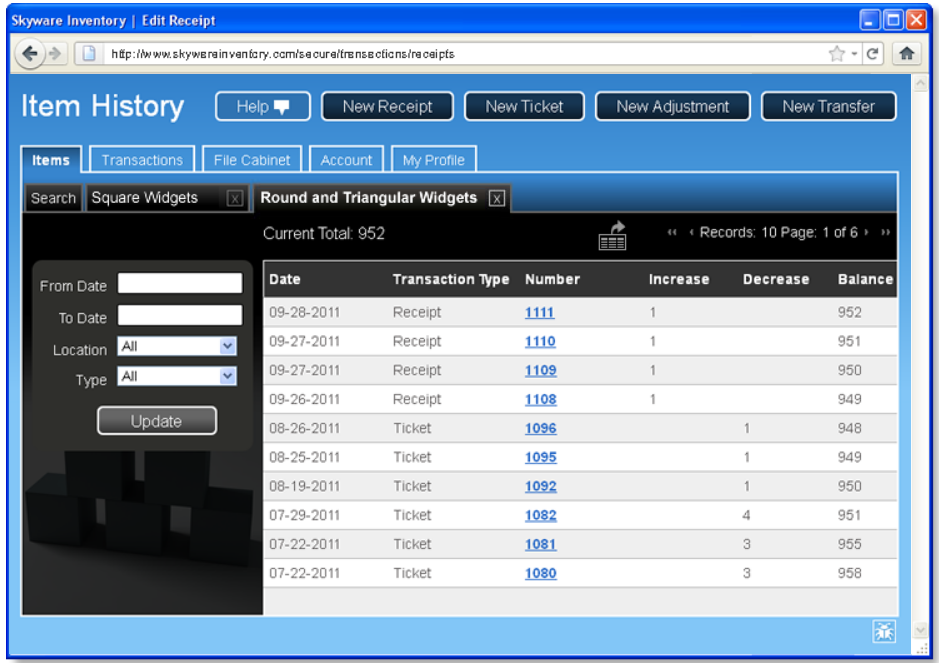

Inventory management software is a tool that helps businesses track and manage their inventory levels. It can be used to track the quantity of items in stock, the location of items, and the cost of items. Inventory management software can help businesses improve their inventory accuracy, reduce their inventory costs, and improve their customer service.

Key Features and Capabilities of Inventory Management Software

Inventory management software typically includes the following features and capabilities:

- Inventory tracking: Inventory management software can track the quantity of items in stock, the location of items, and the cost of items.

- Inventory forecasting: Inventory management software can forecast future demand for items based on historical data.

- Inventory optimization: Inventory management software can help businesses optimize their inventory levels to minimize the risk of stockouts and overstocking.

- Inventory reporting: Inventory management software can generate reports on inventory levels, inventory turnover, and inventory costs.

Benefits of Using Inventory Management Software

There are many benefits to using inventory management software, including:

- Improved inventory accuracy: Inventory management software can help businesses improve their inventory accuracy by providing them with real-time visibility into their inventory levels.

- Reduced inventory costs: Inventory management software can help businesses reduce their inventory costs by optimizing their inventory levels and reducing the risk of stockouts and overstocking.

- Improved customer service: Inventory management software can help businesses improve their customer service by providing them with the information they need to fulfill orders quickly and efficiently.

Inventory Management Best Practices: Business Inventory Accounting Tool

Effective inventory management is crucial for businesses to maintain optimal stock levels, reduce costs, and enhance customer satisfaction. By implementing best practices, businesses can ensure accurate inventory records, efficient operations, and improved profitability.

One of the key best practices is maintaining inventory accuracy. Regular cycle counting, physical inventory verification, and data reconciliation help identify and correct discrepancies, preventing stockouts and overstocking. Accurate inventory data enables businesses to make informed decisions about production, procurement, and sales.

Vendor Management

Establishing strong relationships with suppliers is essential for efficient inventory management. By working closely with vendors, businesses can negotiate favorable terms, ensure timely deliveries, and minimize disruptions in the supply chain. Effective vendor management involves regular communication, performance monitoring, and collaborative problem-solving.

Inventory Optimization

Optimizing inventory levels is crucial to avoid both stockouts and excess inventory. Businesses should use inventory optimization techniques such as ABC analysis, safety stock calculations, and demand forecasting to determine the ideal inventory levels for each item. By optimizing inventory, businesses can reduce carrying costs, free up capital, and improve customer service.

Inventory Management Software

Leveraging inventory management software can significantly enhance inventory management processes. These software solutions provide real-time visibility into inventory levels, automate tasks, and generate reports for analysis. By using inventory management software, businesses can streamline operations, improve accuracy, and make data-driven decisions.

Final Conclusion

By leveraging the power of business inventory accounting tools and adhering to best practices, businesses can gain a competitive edge through improved inventory accuracy, reduced costs, and enhanced operational efficiency. This guide serves as a valuable resource for businesses seeking to optimize their inventory management processes and achieve greater success.

Clarifying Questions

What are the benefits of using a business inventory accounting tool?

Business inventory accounting tools offer numerous benefits, including improved inventory accuracy, reduced costs, enhanced operational efficiency, and better decision-making.

What are the key features of an effective inventory management system?

Effective inventory management systems typically include features such as real-time inventory tracking, automated inventory valuation, reorder point calculation, and reporting capabilities.

What are some best practices for effective inventory management?

Best practices for effective inventory management include maintaining accurate inventory records, implementing cycle counting, managing vendor relationships effectively, and utilizing inventory optimization techniques.