In the realm of business, efficiency reigns supreme, and business inventory programs stand as indispensable tools for optimizing inventory management. These programs provide a comprehensive solution for businesses to streamline their inventory operations, ensuring accurate tracking, cost optimization, and enhanced decision-making.

From small-scale startups to large-scale enterprises, inventory management is crucial for maintaining optimal stock levels, reducing waste, and meeting customer demands. Business inventory programs empower businesses with real-time visibility into their inventory, enabling them to make informed decisions and respond swiftly to market fluctuations.

Introduction to Business Inventory Programs

Business inventory programs are software solutions designed to help businesses manage their inventory efficiently. They provide a centralized platform to track, monitor, and control the flow of goods and materials within a supply chain.

Inventory management is crucial for businesses of all sizes. It ensures that businesses have the right amount of inventory to meet customer demand, avoid stockouts, and minimize waste. Inventory programs can streamline inventory management processes, improve accuracy, and reduce costs.

Benefits of Using Inventory Programs

- Improved inventory accuracy: Inventory programs use real-time data to provide accurate inventory counts, reducing the risk of stockouts and overstocking.

- Increased efficiency: Inventory programs automate many inventory management tasks, such as order processing, stock replenishment, and inventory tracking, saving businesses time and resources.

- Enhanced visibility: Inventory programs provide real-time visibility into inventory levels, allowing businesses to make informed decisions about purchasing, production, and distribution.

- Reduced costs: Inventory programs can help businesses reduce inventory carrying costs, minimize waste, and improve cash flow by optimizing inventory levels.

Types of Business Inventory Programs

Inventory programs assist businesses in tracking, managing, and optimizing their inventory levels. Different types of inventory programs exist, each with unique advantages and disadvantages, catering to specific industry needs.

Perpetual Inventory Programs

Perpetual inventory programs maintain real-time records of inventory levels. Each transaction (purchase, sale, adjustment) is recorded immediately, providing up-to-date inventory data.

- Advantages:Accurate inventory levels, reduced shrinkage, improved decision-making.

- Disadvantages:More complex and time-consuming to implement, higher cost.

Industries that use perpetual inventory programs include retail, manufacturing, and distribution.

Periodic Inventory Programs

Periodic inventory programs update inventory levels periodically, typically at the end of a month or quarter. Physical inventory counts are conducted to determine the actual inventory on hand.

- Advantages:Less complex and time-consuming, lower cost.

- Disadvantages:Inaccurate inventory levels between updates, potential for shrinkage.

Industries that use periodic inventory programs include small businesses, low-volume businesses, and businesses with stable inventory levels.

FIFO (First-In, First-Out) Inventory Programs

FIFO inventory programs assume that the first items purchased are the first items sold. This results in the oldest inventory being sold first.

- Advantages:More accurate cost of goods sold (COGS) during periods of rising prices.

- Disadvantages:May result in higher COGS during periods of falling prices.

Industries that use FIFO inventory programs include food and beverage, fashion, and electronics.

LIFO (Last-In, First-Out) Inventory Programs

LIFO inventory programs assume that the last items purchased are the first items sold. This results in the most recent inventory being sold first.

- Advantages:More accurate COGS during periods of falling prices.

- Disadvantages:May result in higher COGS during periods of rising prices.

Industries that use LIFO inventory programs include mining, oil and gas, and construction.

Features and Functionality of Inventory Programs

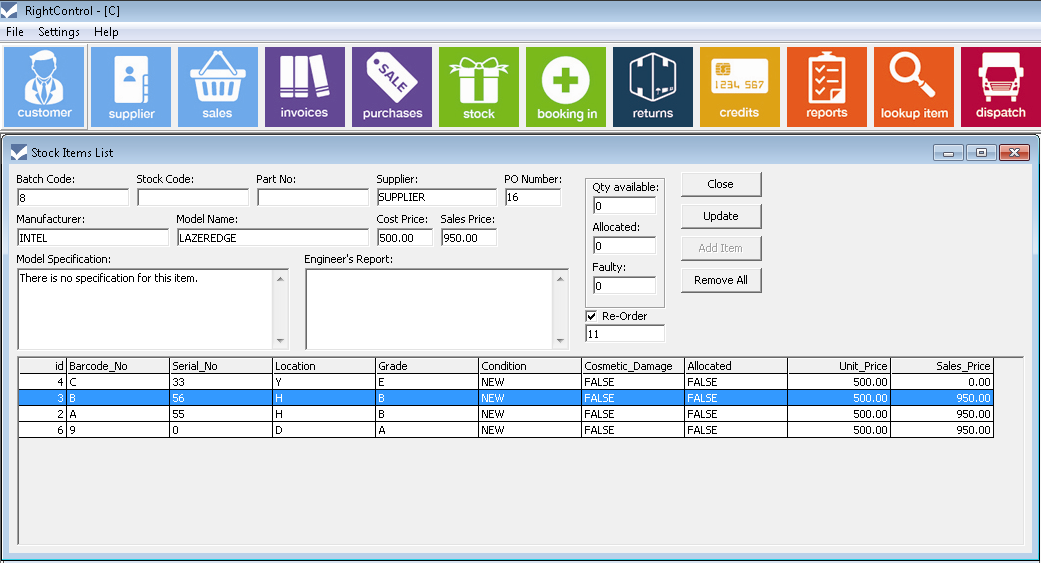

Inventory programs are software applications that help businesses manage their inventory effectively. They offer a wide range of features and functionalities that streamline inventory management processes, improve accuracy, and reduce costs.

Some common features of inventory programs include:

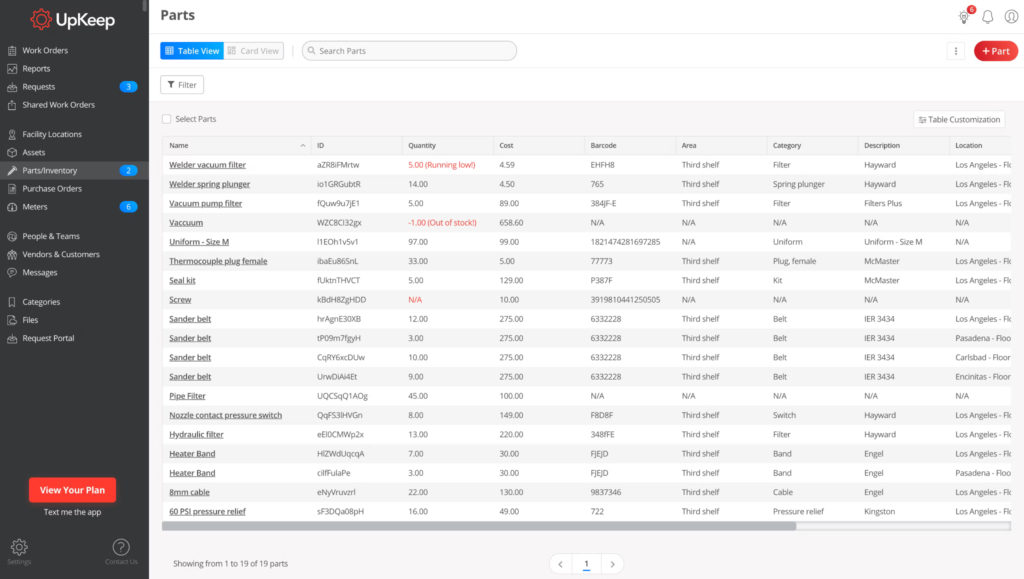

- Product catalog management: Inventory programs allow businesses to create and manage a catalog of products, including information such as product name, description, SKU, and price.

- Inventory tracking: Inventory programs track the quantity of each product in stock, as well as its location within the warehouse or retail store.

- Order management: Inventory programs can process customer orders and generate invoices and packing slips.

- Reporting: Inventory programs generate reports that provide insights into inventory levels, sales trends, and other key metrics.

Barcode Scanning

Barcode scanning is a feature that allows businesses to scan barcodes on products to quickly and accurately identify and track them. This can save time and reduce errors in the inventory management process.

Real-Time Tracking

Real-time tracking is a feature that allows businesses to track inventory levels in real time. This can help businesses avoid stockouts and ensure that they always have the products that customers demand.

Reporting

Inventory programs offer a variety of reporting features that can help businesses track inventory levels, sales trends, and other key metrics. This information can be used to make informed decisions about inventory management and improve business performance.

Examples of Inventory Programs

There are a number of different inventory programs available on the market. Some popular examples include:

- Fishbowl Inventory

- QuickBooks Inventory

- NetSuite Inventory

- SAP Business One

- Oracle NetSuite

These programs offer a variety of features and functionalities that can help businesses of all sizes manage their inventory effectively.

Best Practices for Inventory Management

Effective inventory management is crucial for businesses to optimize costs, minimize waste, and enhance customer satisfaction. Here are some best practices to help you use inventory programs effectively:

Implement a comprehensive inventory management system that provides real-time visibility into inventory levels, tracks stock movements, and automates tasks like reordering and stock replenishment. This helps businesses maintain optimal inventory levels and avoid stockouts or overstocking.

Setting Target Inventory Levels

Establish target inventory levels based on historical demand data, lead times, and safety stock requirements. Safety stock acts as a buffer to mitigate unexpected demand fluctuations or supply chain disruptions. Regularly review and adjust target levels to ensure they align with changing business needs.

Optimizing Inventory Turnover, Business inventory programs

Monitor inventory turnover rates to assess how efficiently inventory is being utilized. High turnover rates indicate efficient inventory management, while low turnover rates may suggest overstocking or slow-moving items. Use inventory management programs to identify slow-moving items and implement strategies to improve their turnover, such as discounts or promotions.

Managing Inventory in Different Scenarios

Businesses may face different inventory management challenges depending on their industry, product mix, and customer demand. Here are some tips for managing inventory in different scenarios:

- Seasonal businesses:Plan inventory levels to meet seasonal demand fluctuations. Use inventory forecasting tools to predict demand and adjust stock levels accordingly.

- Businesses with high-value inventory:Implement robust security measures to prevent theft or loss. Consider using inventory tracking technologies like RFID or GPS to monitor valuable items.

- Businesses with perishable inventory:Establish effective inventory control systems to minimize spoilage and waste. Use FIFO (first-in, first-out) methods to ensure that older inventory is sold first.

Emerging Trends in Inventory Management: Business Inventory Programs

The advent of advanced technologies has revolutionized inventory management practices. Businesses are embracing innovative solutions to optimize stock levels, enhance efficiency, and gain a competitive edge. These emerging trends are shaping the future of inventory programs, empowering businesses to streamline operations and maximize profitability.

One notable trend is the adoption of cloud-based inventory management systems. Cloud platforms provide real-time visibility into inventory levels across multiple locations, enabling businesses to make informed decisions and respond swiftly to market demands. The centralized nature of cloud systems facilitates seamless collaboration among teams and eliminates data silos.

Artificial Intelligence (AI) and Machine Learning (ML)

AI and ML algorithms are transforming inventory management by automating tasks, predicting demand, and optimizing stock levels. AI-powered systems analyze historical data, sales patterns, and market trends to generate accurate forecasts. This enables businesses to anticipate customer needs and maintain optimal inventory levels, minimizing the risk of overstocking or stockouts.

Radio Frequency Identification (RFID)

RFID technology utilizes radio waves to identify and track inventory items. RFID tags attached to products provide real-time visibility into their location and movement throughout the supply chain. This enhanced tracking capability reduces errors, streamlines receiving and shipping processes, and improves inventory accuracy.

Example of Successful Adoption

Amazon, a leading e-commerce giant, has successfully implemented RFID technology in its warehouses. RFID tags on products enable automated tracking and inventory updates, resulting in improved efficiency, reduced labor costs, and enhanced customer satisfaction through faster order fulfillment.

Conclusion

In conclusion, business inventory programs have revolutionized the way businesses manage their inventory. By leveraging advanced technologies and functionalities, these programs empower businesses to optimize stock levels, minimize costs, and gain a competitive edge. As the business landscape continues to evolve, inventory management will remain a cornerstone of operational efficiency, and business inventory programs will continue to play a pivotal role in driving business success.

Frequently Asked Questions

What are the key benefits of using business inventory programs?

Business inventory programs offer numerous benefits, including improved inventory accuracy, reduced stockouts, optimized stock levels, cost savings, and enhanced decision-making.

How do I choose the right inventory program for my business?

Selecting the right inventory program involves considering factors such as business size, industry, inventory volume, and specific business needs. It’s advisable to research different programs, compare features, and consult with experts to make an informed decision.

What are some best practices for effective inventory management?

Best practices include maintaining accurate inventory records, implementing inventory control systems, optimizing stock levels, and leveraging technology to automate processes and gain real-time visibility.