As inventory management for small business excel takes center stage, this opening passage beckons readers with casual formal language style into a world crafted with good knowledge, ensuring a reading experience that is both absorbing and distinctly original.

Inventory management is a crucial aspect of any business, and small businesses are no exception. With the right inventory management system in place, small businesses can optimize their operations, reduce costs, and improve customer satisfaction. This guide will provide you with a comprehensive overview of inventory management for small business excel, including step-by-step instructions on how to create an inventory management system in Excel, manage inventory levels, track inventory transactions, value inventory, and generate reports.

Introduction

Inventory management is a crucial aspect for small businesses, as it directly impacts their profitability and customer satisfaction. It involves tracking, managing, and optimizing the flow of goods from the moment they are received until they are sold to customers.

Effective inventory management enables small businesses to meet customer demand, minimize waste, and maximize profits.

However, small businesses often face challenges in managing inventory due to limited resources, space constraints, and fluctuating demand. Manual inventory management can be time-consuming and error-prone, leading to inaccurate stock levels and potential losses.

Benefits of Using Excel for Inventory Management, Inventory management for small business excel

Using Microsoft Excel for inventory management offers several benefits for small businesses:

- Simplified Data Entry and Tracking:Excel provides an easy-to-use interface for recording inventory items, quantities, and other relevant details.

- Automated Calculations and Formulas:Excel allows users to create formulas for calculating inventory value, reorder points, and other important metrics, reducing manual calculations and errors.

- Data Organization and Filtering:Excel enables users to organize inventory data in tables and filter it based on specific criteria, making it easier to find and manage specific items.

- Visual Representation of Data:Excel offers charts and graphs to visualize inventory levels, trends, and other data, providing insights for decision-making.

- Collaboration and Sharing:Excel allows multiple users to access and update inventory data simultaneously, facilitating collaboration and real-time updates.

Creating an Inventory Management System in Excel

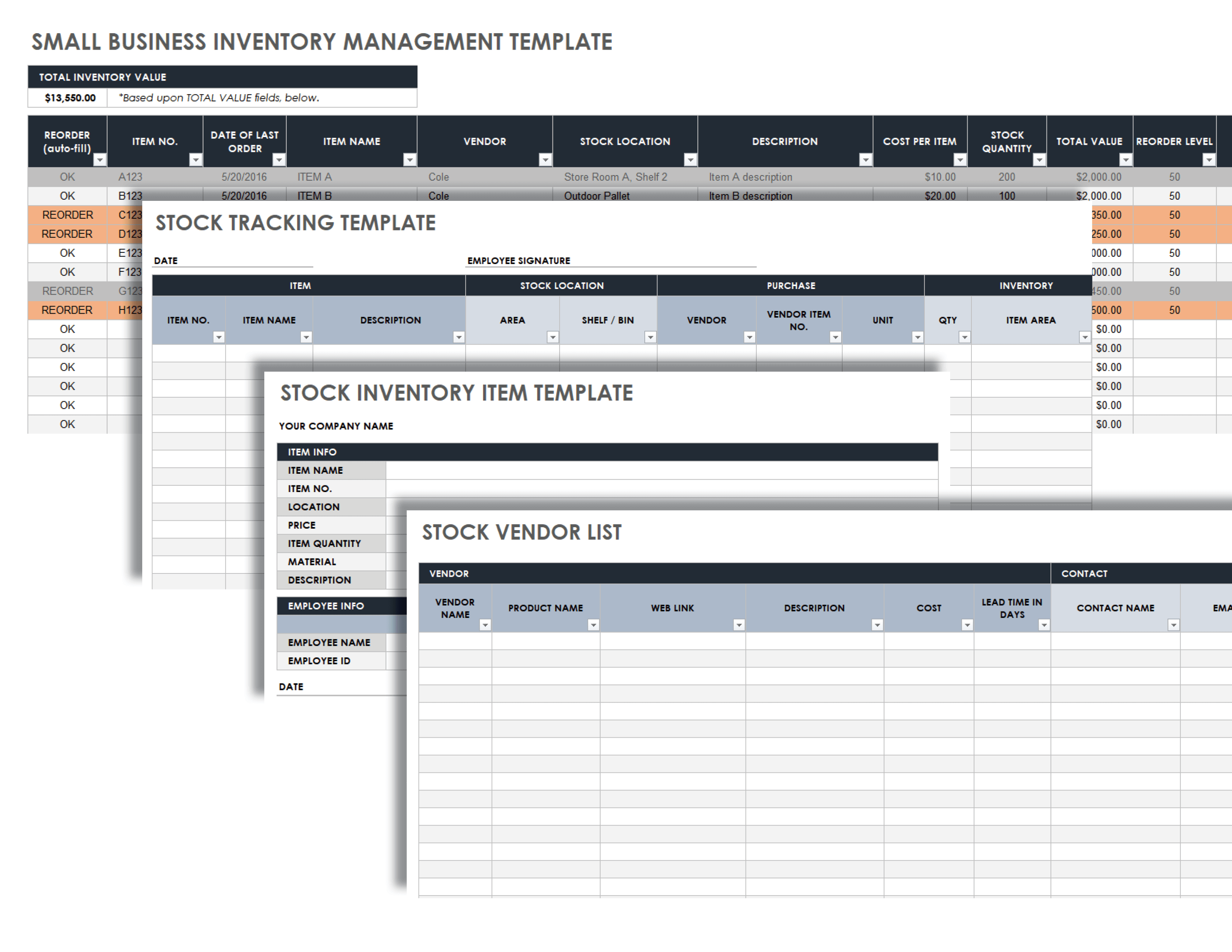

To establish an inventory management system in Excel, follow these steps:

Creating the Inventory Table

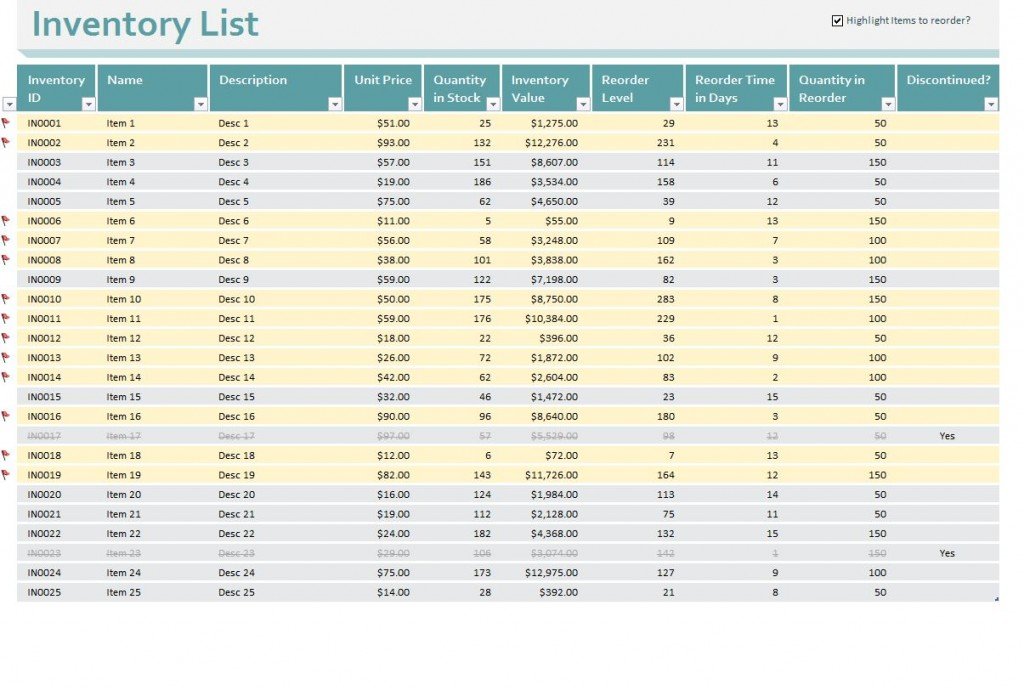

Start by creating a new Excel workbook. In the first worksheet, create a table to store your inventory data. The table should have the following columns:

- Item Code:A unique identifier for each item in your inventory.

- Item Name:The name of the item.

- Description:A brief description of the item.

- Unit Price:The cost of each unit of the item.

- Quantity on Hand:The number of units of the item currently in stock.

- Reorder Point:The quantity at which you should reorder the item.

- Reorder Quantity:The quantity to order when the inventory falls below the reorder point.

Once you have created the inventory table, you can start adding your inventory data.

Managing Inventory Levels

Managing inventory levels is crucial for optimizing cash flow, reducing waste, and ensuring customer satisfaction. This section explores methods for determining optimal inventory levels, calculating safety stock and reorder points, and adjusting inventory levels based on demand forecasts.

Determining Optimal Inventory Levels

Determining optimal inventory levels involves balancing the costs of holding inventory against the risks of stockouts. The Economic Order Quantity (EOQ) is a widely used formula that calculates the optimal order quantity to minimize total inventory costs.

Calculating Safety Stock and Reorder Points

Safety stock is the buffer inventory held to protect against unexpected demand fluctuations or supply chain disruptions. The reorder point is the inventory level at which a new order should be placed. The following formulas can be used to calculate these values:

- Safety Stock = (Maximum Daily Demand – Maximum Lead Time) – (Average Daily Demand – Average Lead Time)

- Reorder Point = Safety Stock + (Average Daily Demand – Average Lead Time)

Forecasting Demand and Adjusting Inventory Levels

Forecasting demand is essential for adjusting inventory levels to meet customer needs. Various forecasting methods, such as moving averages, exponential smoothing, and regression analysis, can be used to predict future demand. Based on these forecasts, businesses can make informed decisions about adjusting inventory levels to avoid overstocking or understocking.

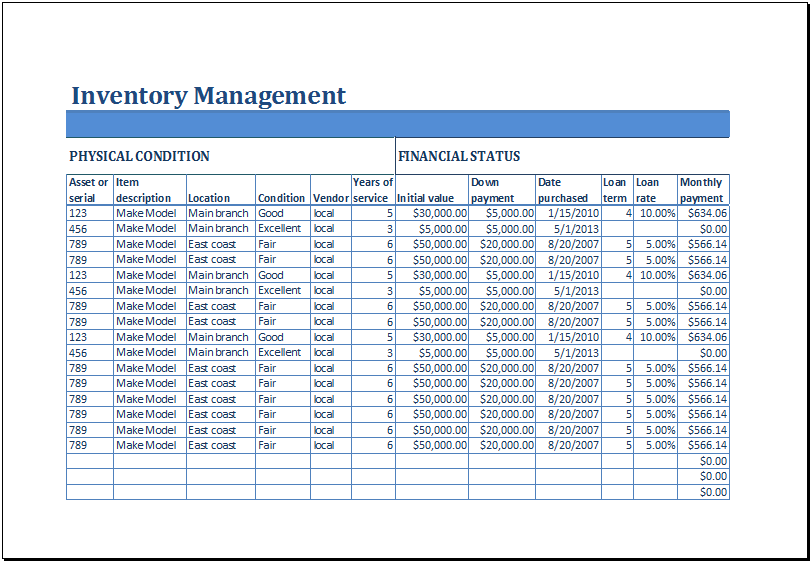

Valuing Inventory: Inventory Management For Small Business Excel

Valuing inventory is crucial for maintaining accurate financial records and making informed decisions. Different methods exist to determine the value of inventory, each with its advantages and disadvantages.

Inventory Valuation Methods

- FIFO (First-In, First-Out):Assumes that the oldest inventory is sold first. This method aligns with the physical flow of inventory in many businesses.

- LIFO (Last-In, First-Out):Assumes that the most recently acquired inventory is sold first. This method can be beneficial during periods of inflation, as it reduces the cost of goods sold and increases net income.

- Weighted Average Cost:Calculates the average cost of inventory based on all units available for sale during a period. This method provides a more stable valuation than FIFO or LIFO.

Calculating Inventory Value Using Excel Formulas

Excel provides formulas to assist in inventory valuation:

=SUMIF(range, criteria, sum_range)

This formula can be used to calculate the total value of inventory based on specific criteria, such as product category or location.

Adjusting Inventory Value

Inventory value should be adjusted periodically to account for shrinkage and obsolescence:

- Shrinkage:Refers to the loss of inventory due to theft, damage, or other factors. This can be estimated using a percentage of inventory value.

- Obsolescence:Refers to inventory that has become outdated or unsellable. This can be identified by reviewing sales trends and adjusting inventory value accordingly.

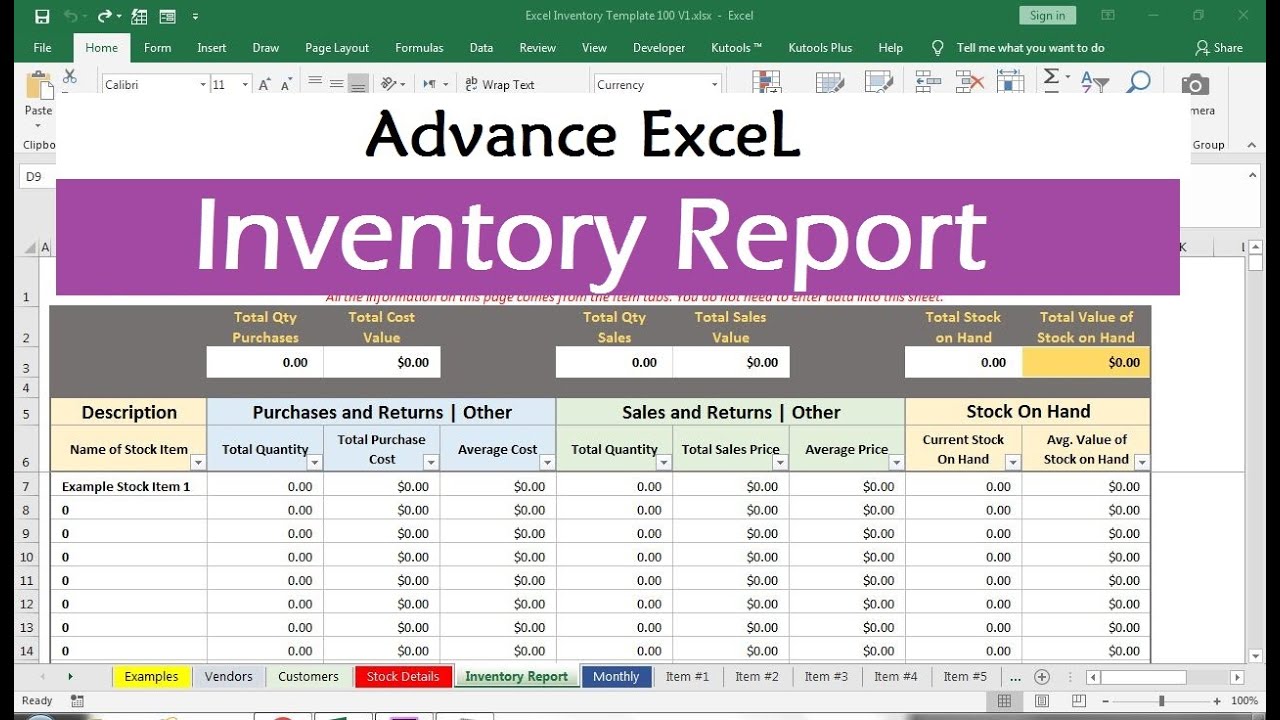

Reporting and Analysis

Effective inventory management requires regular reporting and analysis to monitor inventory levels, identify trends, and make informed decisions. Excel provides robust features for creating custom reports and analyzing inventory data.

To create an inventory report in Excel, start by organizing your inventory data in a spreadsheet. Include columns for product name, description, quantity on hand, unit cost, and total value.

Generating Inventory Reports

- Inventory Summary:Provides an overview of the inventory, including total quantity, total value, and average unit cost.

- Stock Status Report:Lists the current stock levels of each item, highlighting items that are low on stock or out of stock.

- Turnover Ratio:Calculates the number of times inventory is sold and replaced over a period of time, indicating the efficiency of inventory management.

Analyzing Inventory Data

Excel charts and graphs can help visualize inventory data and identify trends. Create charts to track inventory levels over time, compare different products, or analyze turnover ratios.

By analyzing inventory reports and charts, businesses can identify areas for improvement, such as reducing excess inventory, optimizing stock levels, and improving inventory turnover.

Conclusive Thoughts

In conclusion, inventory management is a critical component of any small business. By implementing the strategies and techniques Artikeld in this guide, small businesses can gain control of their inventory, optimize their operations, and achieve greater success.

Expert Answers

What are the benefits of using Excel for inventory management?

Excel is a powerful tool that can be used for a variety of inventory management tasks, including creating inventory lists, tracking inventory levels, and generating reports. Excel is also relatively easy to use, making it a good option for small businesses that do not have a dedicated inventory management system.

How do I create an inventory management system in Excel?

To create an inventory management system in Excel, you will need to create a spreadsheet with columns for each of the following data points: item name, item description, item number, quantity on hand, reorder point, and safety stock. You can also add additional columns for tracking other information, such as item cost, item location, and item supplier.

How do I track inventory levels in Excel?

To track inventory levels in Excel, you can use the SUMIF function to calculate the total quantity of each item on hand. You can also use the IF function to create conditional formatting rules that will highlight items that are below their reorder point or safety stock.