In the realm of small businesses, inventory control reigns supreme as the key to unlocking profitability and efficiency. It’s like a game of Tetris, but instead of colorful blocks, you’re juggling products, stock levels, and customer demands. Buckle up for a wild ride as we dive into the world of small business inventory control, where every piece counts!

From understanding inventory management methods to optimizing stock levels and implementing best practices, this guide will empower you to become a maestro of inventory control. Get ready to transform your small business into a lean, mean, inventory-managing machine!

Inventory Control Methods

Inventory control methods are essential for managing your small business’s stock levels, ensuring you have the right products in the right quantities at the right time. There are several inventory control methods to choose from, each with its advantages and disadvantages.

The most common methods are FIFO, LIFO, and weighted average cost.

FIFO (First-In, First-Out)

FIFO assumes that the first items purchased are the first items sold. This means that the cost of goods sold is based on the cost of the oldest inventory on hand. FIFO can be a good choice for businesses that sell perishable goods or products with a short shelf life.

- Advantages:Matches the physical flow of inventory, provides a more accurate representation of current inventory value, and is relatively easy to implement.

- Disadvantages:Can result in higher cost of goods sold during periods of inflation and lower cost of goods sold during periods of deflation, and may not accurately reflect the actual age of inventory on hand.

LIFO (Last-In, First-Out)

LIFO assumes that the last items purchased are the first items sold. This means that the cost of goods sold is based on the cost of the newest inventory on hand. LIFO can be a good choice for businesses that sell non-perishable goods or products with a long shelf life.

- Advantages:Results in lower cost of goods sold during periods of inflation and higher cost of goods sold during periods of deflation, and can provide tax benefits.

- Disadvantages:Does not match the physical flow of inventory, can result in a mismatch between the cost of goods sold and the actual age of inventory on hand, and can be more difficult to implement than FIFO.

Weighted Average Cost

Weighted average cost assumes that all units of inventory are purchased at the same cost. This means that the cost of goods sold is based on the average cost of all inventory on hand. Weighted average cost can be a good choice for businesses that sell a variety of products with different costs.

- Advantages:Provides a more stable cost of goods sold, is relatively easy to implement, and can be used for both FIFO and LIFO inventory systems.

- Disadvantages:Does not accurately reflect the actual cost of goods sold, can be more difficult to calculate than FIFO or LIFO, and may not be appropriate for businesses that sell a variety of products with different costs.

Inventory Management Systems

Tired of losing track of your stock like a headless chicken? Inventory management systems are here to save the day! These software solutions are like your trusty sidekick, keeping an eagle eye on your inventory levels, so you can avoid embarrassing stockouts and keep your customers happy.

Cloud-Based vs. On-Premise Inventory Systems

When it comes to choosing an inventory management system, you have two main options: cloud-based or on-premise. Cloud-based systems are like renting a car—you access them online and pay a monthly fee. On-premise systems, on the other hand, are like buying your own car—you install them on your own server and have full control over them.

Cloud-based systems are often more affordable and easier to set up, making them a great choice for small businesses. On-premise systems offer more customization and control, but they can be more expensive and complex to manage.

Key Features to Look For

When shopping for an inventory management system, keep an eye out for these key features:

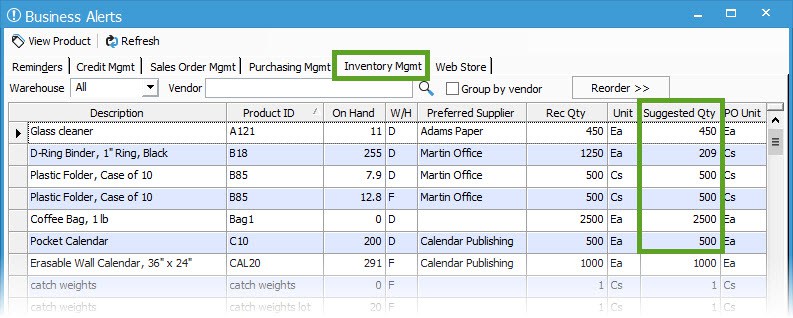

- Real-time tracking:Keep tabs on your inventory levels in real time, so you can avoid surprises.

- Automated alerts:Get notified when stock levels are low or when items are about to expire.

- Reporting and analytics:Track your inventory performance and identify trends to make better decisions.

- Integration with other systems:Connect your inventory management system with your accounting software, CRM, and other business tools.

- Mobile access:Manage your inventory on the go with a mobile app.

Inventory Optimization Techniques

Inventory optimization is the key to maximizing efficiency and minimizing waste in your small business. By implementing effective inventory control methods, you can ensure that you have the right products in stock at the right time, without overstocking or running out.

Safety Stock, Small business inventory control

Safety stock is the buffer you keep on hand to protect against unexpected fluctuations in demand or supply. It’s like an insurance policy for your inventory, ensuring you can meet customer demand even when things don’t go according to plan.

Safety stock formula: Safety stock = (Maximum daily usage x Maximum lead time)- (Average daily usage x Average lead time)

Reorder Point Calculations

The reorder point is the level of inventory at which you need to place a new order to avoid running out. Calculating the reorder point is crucial for preventing stockouts and ensuring smooth operations.

- Average daily usage:Calculate the average number of units you sell each day.

- Lead time:Determine the time it takes from placing an order to receiving the goods.

- Safety stock:Calculate the safety stock as described above.

Reorder point formula:Reorder point = (Average daily usage x Lead time) + Safety stock

Reducing Inventory Waste

Inventory waste is the bane of any small business. By implementing these techniques, you can minimize waste and improve your bottom line:

- First in, first out (FIFO):Use this method to ensure that the oldest inventory is sold first, preventing spoilage and obsolescence.

- Just-in-time (JIT) inventory:Only order inventory when you need it, reducing storage costs and waste.

- Vendor-managed inventory (VMI):Let your suppliers manage your inventory levels, ensuring you always have the right products on hand.

Remember, inventory optimization is an ongoing process. By regularly monitoring your inventory levels and adjusting your strategies as needed, you can ensure that your small business has the inventory it needs to succeed.

Inventory Tracking and Reporting

Inventory tracking and reporting are crucial for maintaining accurate inventory levels and ensuring smooth business operations. Let’s dive into the world of barcodes, RFID tags, and the importance of regular inventory audits.

Barcode and RFID Tagging

Barcodes and RFID (Radio Frequency Identification) tags are like the superheroes of inventory tracking. Barcodes, those black and white stripes, can be scanned quickly and easily, providing instant information about the product. RFID tags, on the other hand, are like tiny spies that use radio waves to transmit data wirelessly, giving you real-time updates on your inventory.

Regular Inventory Audits

Think of inventory audits as your inventory’s annual physical. They’re essential for ensuring that your records match reality. It’s like counting all the sheep in your flock to make sure none have gone astray.

Sample Inventory Report

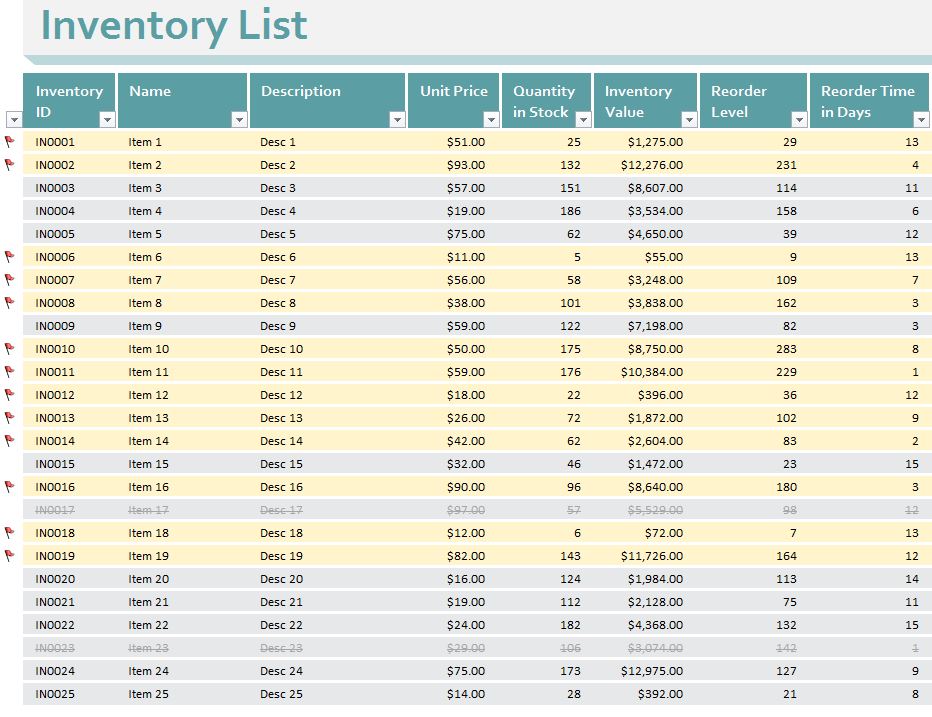

A well-designed inventory report is like a treasure map, guiding you through the labyrinth of your inventory. Here’s a sample report that includes key metrics:

- Product Name: The name of the product being tracked.

- Quantity on Hand: The number of units currently in stock.

- Average Unit Cost: The average cost of each unit.

- Total Value: The total value of the inventory on hand.

- Reorder Point: The quantity at which you need to reorder the product.

- Demand Forecast: The projected demand for the product in the future.

Inventory Control Challenges

Inventory control can be a headache for small businesses, especially when it comes to shrinkage and theft. Shrinkage is the unintentional loss of inventory, while theft is the intentional removal of inventory without authorization. Both can eat into your profits and make it difficult to keep track of your stock.There are a number of strategies you can use to overcome inventory shrinkage and theft, including:

- Use a good inventory management system.This will help you track your inventory levels and identify any discrepancies.

- Conduct regular inventory audits.This will help you identify any missing or stolen items.

- Implement security measures.This could include things like security cameras, motion detectors, and access control systems.

- Train your employees on inventory control procedures.This will help them understand the importance of inventory control and how to prevent shrinkage and theft.

Handling Inventory Discrepancies

Even with the best inventory control measures in place, there will be times when you experience inventory discrepancies. This could be due to a number of factors, such as human error, theft, or damage.When you discover an inventory discrepancy, it’s important to investigate the cause and take steps to prevent it from happening again.

Here are some tips for handling inventory discrepancies:

- Document the discrepancy.This includes the date, time, and location of the discrepancy, as well as the quantity and value of the missing or damaged items.

- Investigate the cause of the discrepancy.This may involve talking to employees, reviewing security footage, or conducting a physical inventory.

- Take steps to prevent the discrepancy from happening again.This may involve implementing new inventory control procedures, training employees, or improving security measures.

By following these tips, you can minimize the impact of inventory control challenges on your small business.

Inventory Control Best Practices

Maintaining accurate and efficient inventory control is crucial for businesses of all sizes. By implementing best practices, businesses can minimize losses, improve customer satisfaction, and optimize their financial performance.

Cycle Counting

Cycle counting is a process of periodically counting inventory to verify its accuracy. It helps identify discrepancies between physical inventory and records, enabling businesses to make necessary adjustments.

- Establish a regular cycle counting schedule based on inventory turnover and risk.

- Assign specific areas or items to be counted each cycle to prevent overlooking any items.

- Use technology, such as handheld scanners or mobile apps, to streamline the counting process and minimize errors.

Improving Inventory Accuracy

Accurate inventory records are essential for effective inventory management. Here are some tips to improve accuracy:

- Train staff on proper inventory handling and counting techniques.

- Implement a system of checks and balances to verify inventory counts and transactions.

- Use technology, such as RFID tags or inventory management software, to automate inventory tracking and reduce manual errors.

Inventory Control in Financial Planning

Inventory control plays a significant role in financial planning by providing accurate data for:

- Cost of Goods Sold (COGS):Accurate inventory records ensure that COGS is calculated correctly, which impacts profitability and tax liability.

- Cash Flow Management:Inventory levels influence cash flow as businesses must invest in inventory before selling it.

- Asset Valuation:Inventory is a valuable asset, and accurate records are crucial for financial reporting and valuation.

Ultimate Conclusion

And there you have it, folks! Small business inventory control, a symphony of organization and profitability. Remember, the key is to find a rhythm that works for your unique business, ensuring that your inventory dances to the tune of efficiency.

Embrace the challenge, master the methods, and watch your small business soar to new heights of success!

Top FAQs: Small Business Inventory Control

What’s the secret to avoiding inventory nightmares?

Regular inventory audits are your secret weapon. They’re like a detective’s magnifying glass, uncovering any discrepancies and ensuring your inventory records match reality.

How can I tame the beast of inventory shrinkage?

Implement robust security measures and establish clear protocols for handling inventory. It’s like building a fortress around your precious stock, keeping the bad guys at bay.

What’s the magic formula for setting reorder points?

It’s a delicate balance of lead time, demand patterns, and safety stock. Find the sweet spot where you avoid stockouts without overstocking and becoming a warehouse for dust bunnies.